Steel doors

Over the years, Métalec has established a solid reputation in the steel door manufacturing area of expertise for commercial, industrial and institutional purposes.

The Métalec steel doors are offered in several sizes with a variety of designs and cores.

They are also available with a 20, 45, 90,or 180 min. fire rating. A label is affixed on the product to certify the fire resistance period.

OPTIONS

- All of these designs are also available in Z275 (G90) galvanized steel;

- Vinyl caps installed at the top of the doors for exterior openings;

- Steel caps installed at the top and the bottom of the doors;

- Mechanical lock seams welded at every 152 mm (6”) center to center grinded, filled with metallic paste, ground smooth and primed;

- Other hardware preparations are also available upon request.

GLAZED OPENINGS

MAXIMUM LIMITATIONS OF GLAZED OPENINGS IN FIRE DOORS

- 180 min. fire rated door (no glazing allowed)

- 90 min. fire rated door (max. 645 cm2 (100 in²) per door)

- 45 min. fire rated door ( max. 8361 cm2 (1296 in²) per opening and max. dimensions 54’’)

- Several designs of doors with glazed openings are available and Métalec offers you different trim kits:

“NL” – “LNL” – “DNL” – “HG” – “FGWR” – “VL” – “CGL” – “FG” – “JDS” – “OG” type (See Glazed opening types hereafter)

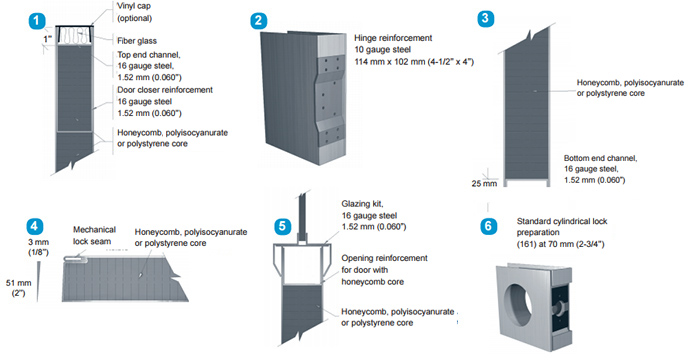

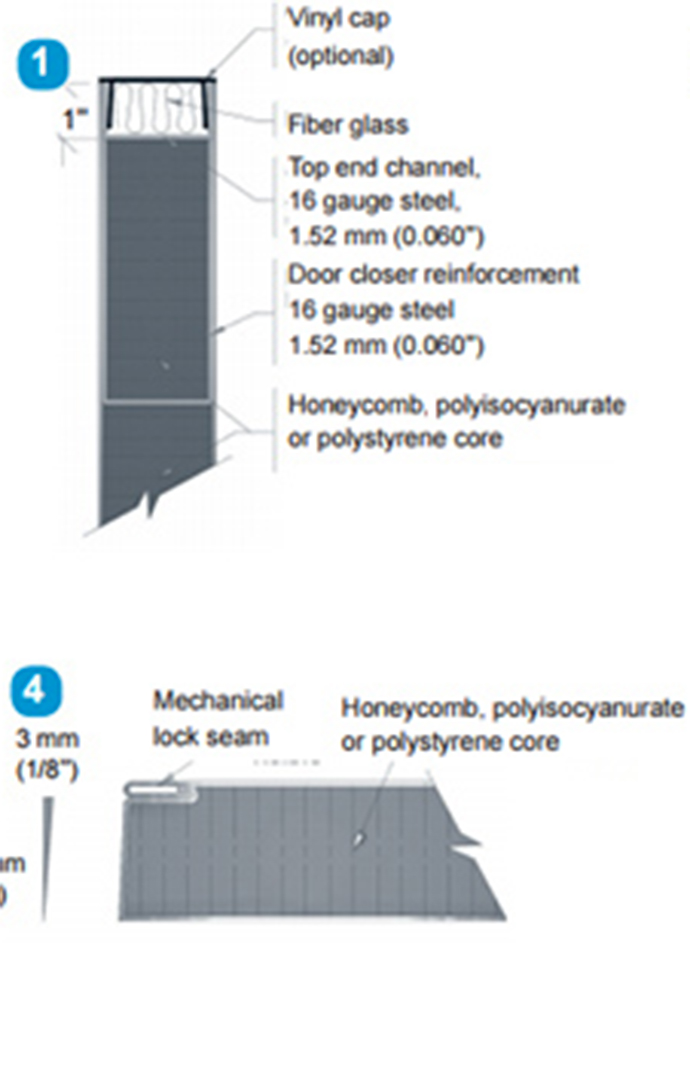

“PS” SERIES – TECHNICAL DETAILS

- Métalec steel doors are manufactured using 20, 18, 16 or 14 gauge galvanized steel;

- The door faces are perfectly smooth, without visible joints;

- The door panels are vertically assembled one to each other by a mechanical lock seam with flush welding near the hardware perforations;

- The door edges have a bevel of 3 mm x 51 mm (1/8” x 2”);

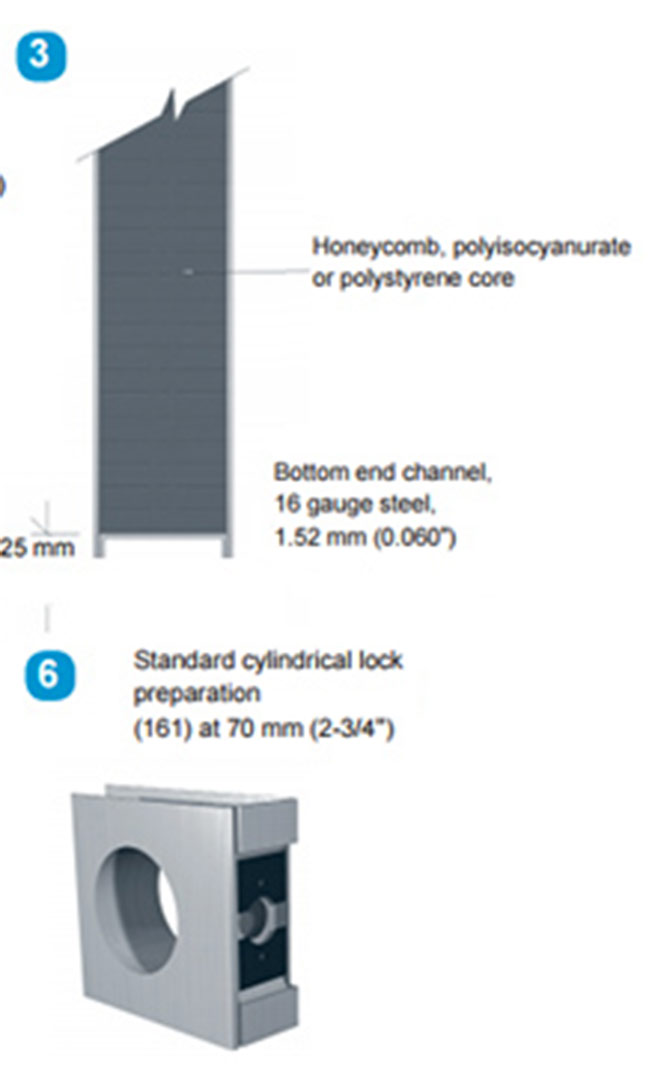

- 16 gauge steel end channels are welded by electric resistance at the top and the bottom of the door every 152 mm (6”) center to center;

- The non-insulated steel doors have a full honeycomb core made of 16 kg/m3 (1.0 lb/cu.ft) density kraft paper with 25 mm (1”) cell size, laminated to the door faces by a polyurethane base adhesive;

- The insulated doors have a 54 kg/m3 (3,4 lb/cu.ft) density polyisocyanurate sheet core with a thermal resistance of RSI 2.0 (R-12.9); or a 16 kg/m3 (1,0 lb/cu.ft) density polystyrene sheet core with a thermal resistance of RSI 1.54 (R-8,75), laminated to the door faces by a polyurethane base adhesive; • The doors are mortised for three standard hinges of 114 mm x 102 mm (4- 1/2” x 4”);

- The hinge reinforcements are made with 10 gauge steel, and the top hinge is reinforced to have additional stiffening bend for high frequency strength;

- The doors are prepared for a standard cylindrical lock or reinforced for a surface-mounted panic bar or for a “push/pull” handle;

- Door closer reinforcement made of 16 gauge steel channel are installed at the top of all steel doors. When the door is reversible, a door closer reinforcement is added at the other end of the door. In the insulated steel doors, all the channels used as reinforcements are filled with the same insulating material as the door.

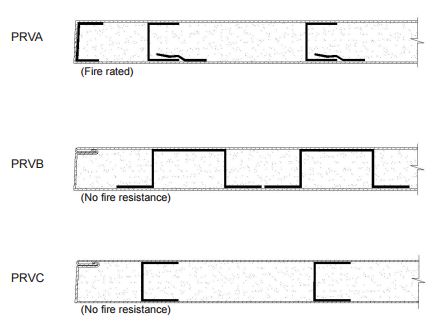

“PRV” SERIES – TECHNICAL DETAILS

- Heavy duty doors from the “PRV” series are available in 18, 16 and 14 gauge steel;

- These doors are designed to withstand high frequency use. They have been used in schools, hospitals, detention centres and recreational buildings;

- Using essentially the same manufacturing process as the ‘’PS’’ series, these doors have vertical 20,18 or 16 gauge steel reinforcements bonded to the door faces at every 152 mm (6”) on center, or welded when a fire rated certification is required;

- The voids between the vertical reinforcements can be filled with polyisocyanurate, polystyrene, honeycomb kraft paper or a fiberglass insulating material;

- The door faces are assembled vertically one to each other by a mechanical lock seam with flush welding near the hardware perforations.

Options

- The door faces are vertically assembled one to each other by a fully welded joint on each side and ground smooth.

- A 14 gauge steel vertical channel reinforcement is welded at the joint on each side to strengthen the assembly. A primer is applied all over the joint.

- These doors are also available with a fire resistance of 45, 90 or 180 min.

“PCR” SERIES – TECHNICAL DETAILS

- The doors from the “PCR” series have a temperature rise core designed to limit temperature rise on the non exposed door face up to 250º C, thus allowing the people being in the building to safely evacuate the area;

- The doors are designed and tested to provide a fire resistance period up to 3 hours (180 min.);

- The doors are provided with a label indicating the degree of temperature and duration of fire resistance: 250°F for 30 min. or 450°F for 60 min. (250°C for 60 min.);

- Essentially built as the “PS” series the “PCR” doors have a mineral fibre core approved by WHI laboratory. This core is laminated to the door faces by a polyurethane base adhesive.