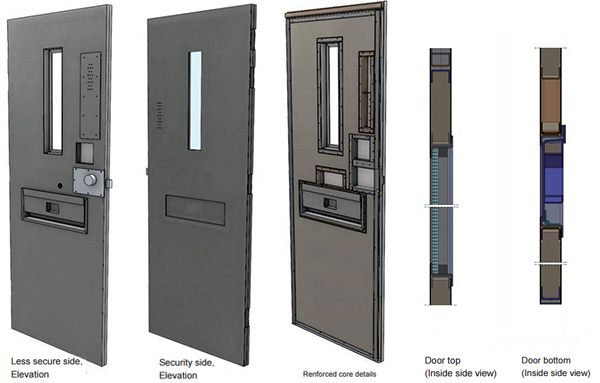

Security doors

Designed to withstand heavy duty and high frequency usage, this door type provides solidity and longevity demanded in police stations and institutional security projects.

TECHNICAL DETAILS

- 1.6mm (16g) ZF120 satin finish galvanized steel (A40) or 2mm (14g) steel;

- The doors will be manufactured with a 45mm (1-3/4”) or 50mm (2”) thickness;

- The doors are perfectly smooth without visible joints on their faces and asperity on their security side;

- The door faces are vertically assembled one to each other with a fully welded joint on each side, ground smooth with a 10 gauge steel reinforcement;

- The door edges have a bevel of 3mm x 51mm (1/8” x 2”) allowing unconstrained operation;

- The door has a plywood core laminated on the door faces with a polyurethane base adhesive offering a maximum bond. The perimeter of the core and the openings for glass and hardware are reinforced with a 2.5mm steel profile (12 gauge), the profiles are welded at their junctions and screwed to the panel;

- The hinge reinforcement is part of the structual perimeter of the door. The steel profile is 2.5mm thick with a 6mm (1/4”) steel reinforcement;

- The prison lock on the security side is reinforced with a 3mm steel plate (1/8”) on the door core, thereby increasing the level of strength and safety;

- A 3mm (10g) steel end channel is welded to the top and bottom of the door;

- A 3mm (10g) steel reinforcement is attached to the door core to receive the closer and door pull;

- No fire certification available.

OPTION, GLAZED OPENINGS

- The periphery of the opening is composed of 2.5mm (12g) “L” shaped steel, welded to the door skins;

- The opening on the security side is smaller than the opposite (corridor/less secure) side to safely support the glass;

- The glazing beads are made with solid steel of 19 mm x 19 mm (3/4” x 3/4”) and fixed with TORX security screws.

N.B.: The opening glass dimensions will vary depending on the customer requirements.

OPTION, SERVING HATCH

- The periphery of the opening is composed of 2.5mm (12g) “Z” shaped steel, welded to the door skins;

- The serving hatch is composed of 2 steel thicknesses. The security side in 5mm (3/16”) and the corridor side in 3mm (1/8”);

- The core is composed of a laminated plywood panel secured with a polyurethane adhesive;

- The hatch can either be manufactured for an integrated handle or reinforced for push/pull hardware;

- The continuous hinge is sturdy and welded to the hatch;

- Two choices are available for the opening, 90 or 180 degrees;

- The preparation of the mortise lock is located in the door and the strike preparation in the hatch.

OPTION, SOUND GRID

- The periphery of the opening is composed of 2.5mm (12g) “U” shaped steel, welded to the door skins;

- The security side has 5mm (3/16”) perforations in staggered rows, the last row of perforations is located at the same height as the bottom reinforcement to allow draining;

- The door skin on the less secure side includes a 3mm (1/8”) stainless plate with 5mm staggered perforations plus a 30mm (13/16”) deflector, secured with TORX security screws.